WELCOME

daniel franz portfolio

Hi,

Daniel here. Welcome to my portfolio, where I showcase my journey, skills, and the projects I’m proud to have been a part of. Feel free to explore and reach out if you have any questions or collaboration ideas!

PROJECTS

Saddles

2022-2024

at CUBE bikes

Protection Gear

2022/2023

at CUBE bikes

ACID CAHDEN

2021

at CUBE bikes

Alioth

2021

at University, team of two

Trailbike Frame

2019

at dreiformstudio GmbH

Paramo

2020

at University, team of two

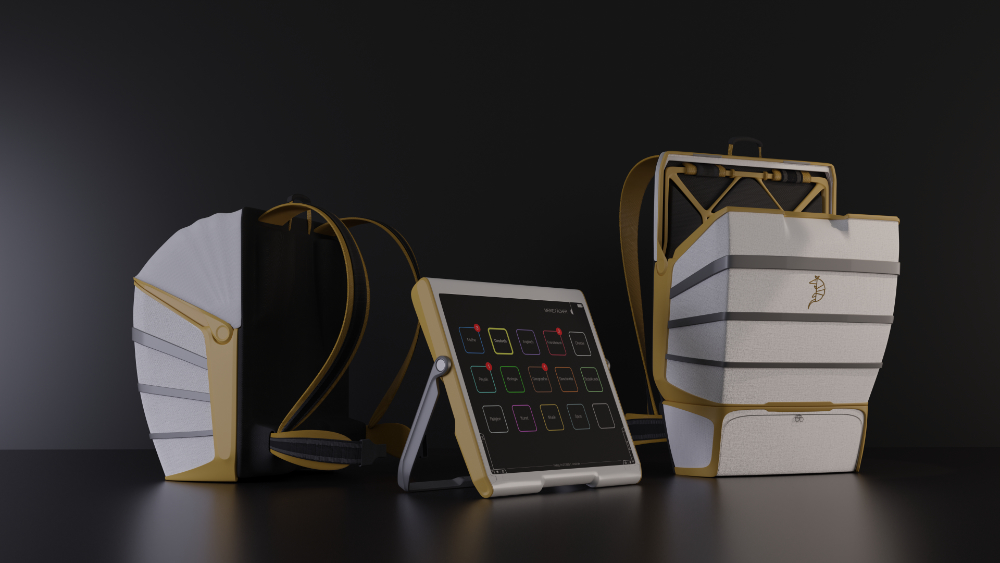

Armadillo

2020

at University, team of two

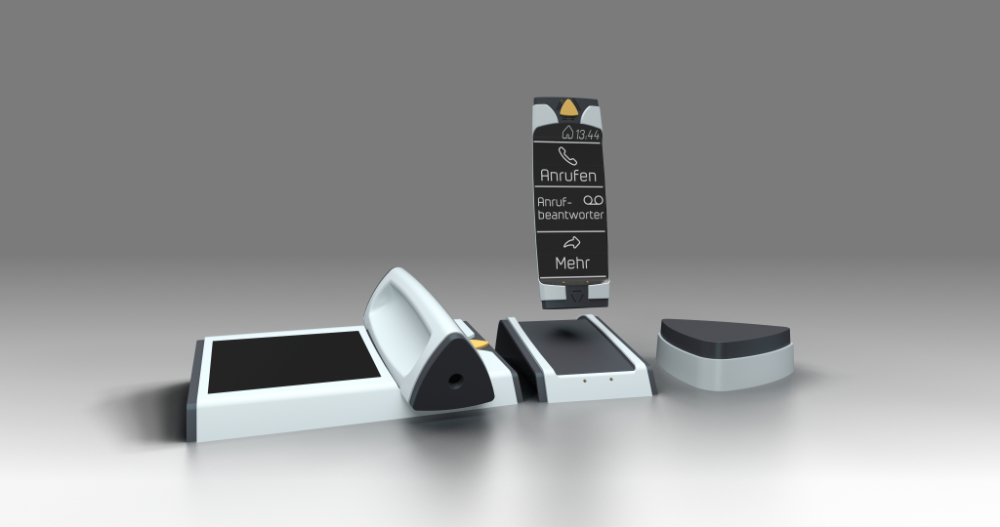

Zwitscher

2019

at University, team of two

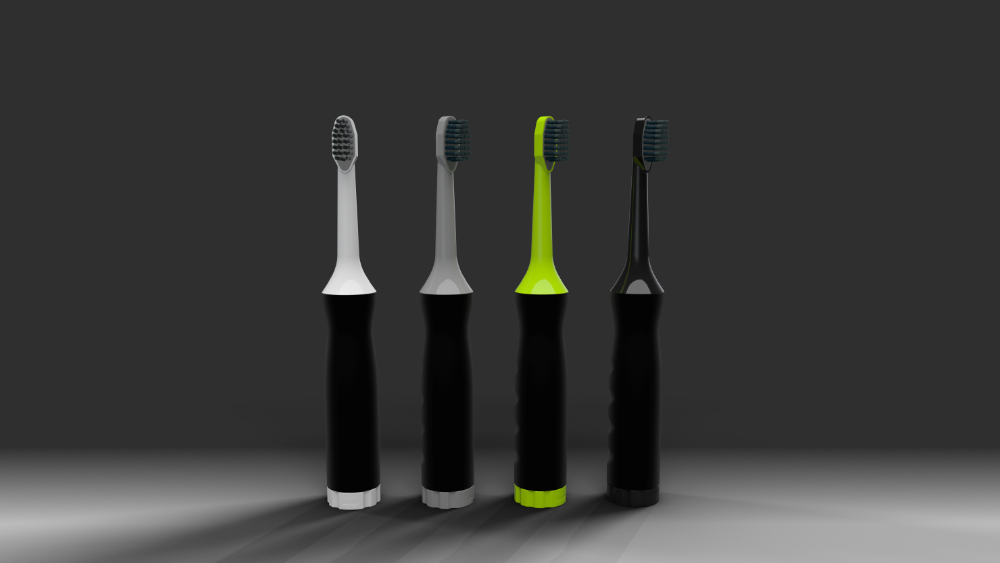

cAIR

2018

at University, individual project

Formula Student Ingolstadt

2015-2017

at University, teamwork

ABOUT ME

Daniel Franz

Hello! My name is Daniel Franz, a passionate product manager and designer based in Marktredwitz, Germany. With a background in both mechatronics and product design, I bring a unique blend of technical expertise and creative vision to every project I undertake. Currently, I work in the bicycle industry at CUBE Bikes, where I focus on developing innovative accessories that enhance the cycling experience. Since February of this year, I have been team leader of the Contact Points division. My area of responsibility mainly comprises saddles and grips, two of the three important points of contact with the bicycle. The realisation of innovative new components involves extensive research, consideration of anatomical and biomechanical requirements, design and technical feasibility and, last but not least, extensive testing.

work experience

From 02/2024 Team leader contact-points at CUBE bikes (Sport Equipment ACS GmbH & Co KG)

From 09/2021 Product design and management for bicycle accessories at CUBE bikes (Sport Equipment ACS GmbH & Co KG)

04/2021 - 08/2021 Bachelor thesis at CUBE bikes (Sport Equipment ACS GmbH & Co KG)

09/2020 - 03/2021 Working as student assistant at Creapolis Coburg: maintaining the equipment, giving workshops and providing bicycle consultation

10/2019 - 04/2020 Internship at dreiform GmbH in Munich: 3D-Modelling, Computational Design

11/2018 - 07/2019 Working as student assistant at new:LAB, University Coburg: working mainly with 3D-scanners (Artec Spider&Eva) and 3D-printers, supporting students projects

04/2015 - 10/2017 Participating at Schanzer Racing Electric, part of Formula Student, teamleader Chassis and Monocoque (since 09/2016), teamleader Aerodynamics (09/2015 - 09/2016), active participation at creating the associations brand identity, designing the foliation of SRe16, Sre17 and SRd17, learned a lot about fiber reinforced plastics

06/2014 - 07/2014 Internship at Forster Pulverbeschichtung (Powdercoating) in Augsburg, surface preparation (sanding, sandblasting, cleaning), customer support

01/2014 - 05/2014 Internship at Modell- und Formenbau Keller (model- and mould making), working with metal, plastic and wood, independent planning and executing of orders, quality assurance

09/2013 - 12/2013 Working at Zettl GmbH, minijob activity at warehouse logistics area

education

10/2017 - 08/2021 bachelor‘s degree integrated product design, University Coburg, grade point average: 1,6

10/2014 - 08/2017 bachelor‘s degree mechatronics, Technical University Ingolstadt, terminated

09/2004 - 06/2013 Justus-von-Liebig-Gymnasium, Neusäß (secondary school) graduation: Abitur 2013, grade point average: 2,6

bachelor thesis

As riding my bike(s) is a big hobby of mine I my bachelor thesis at CUBE Bikes in Waldershof. The subject of the thesis is: Development of a sporty lightweight bicycle saddle made mainly of fiber-plastic composite, taking into consideration human factors, shape and structural design.

CUBE Bikes

internship

During the fifth semester I completed the mandatory internship at dreiformstudio GmbH. There I got an insight into 3D modeling in the automotive industry. I was able to further educate myself especially in the areas of polymodeling and computational design. Autodesk Maya or Blender is often used as a concept modeling tool to realize the visions of the designer quickly. A big advantage of this method is the fast adaptability. Another interesting use of the tool is a fast shape display and proportion developement. The software used for computational design is Grasshopper, a plugin for Rhino 3D.

dreiformstudio GmbH

hobbies: biking

Outside of work, you'll find me hiking and biking through nature, exploring new trails, or tinkering with my bikes. I fortunately have several bikes with different areas of use. So I can either ride full throttle on the road or meander through technical passages, depending on my mood. But not only the riding is interesting to me: My bikes, yes there are a few, get maintained and serviced by myself. I also test a lot of new part and prototypes from myself and my colleagues. During my time in Coburg, I worked with a professional bicycle mechanic. We gave advice at Creapolis Coburg and helped mainly other students to repair their bikes, which taught me a lot. Now I can proudly say that I work in exactly this industry. Maybe one day you'll ride with one of the products I helped develop and I wish you lots of fun and success with it.

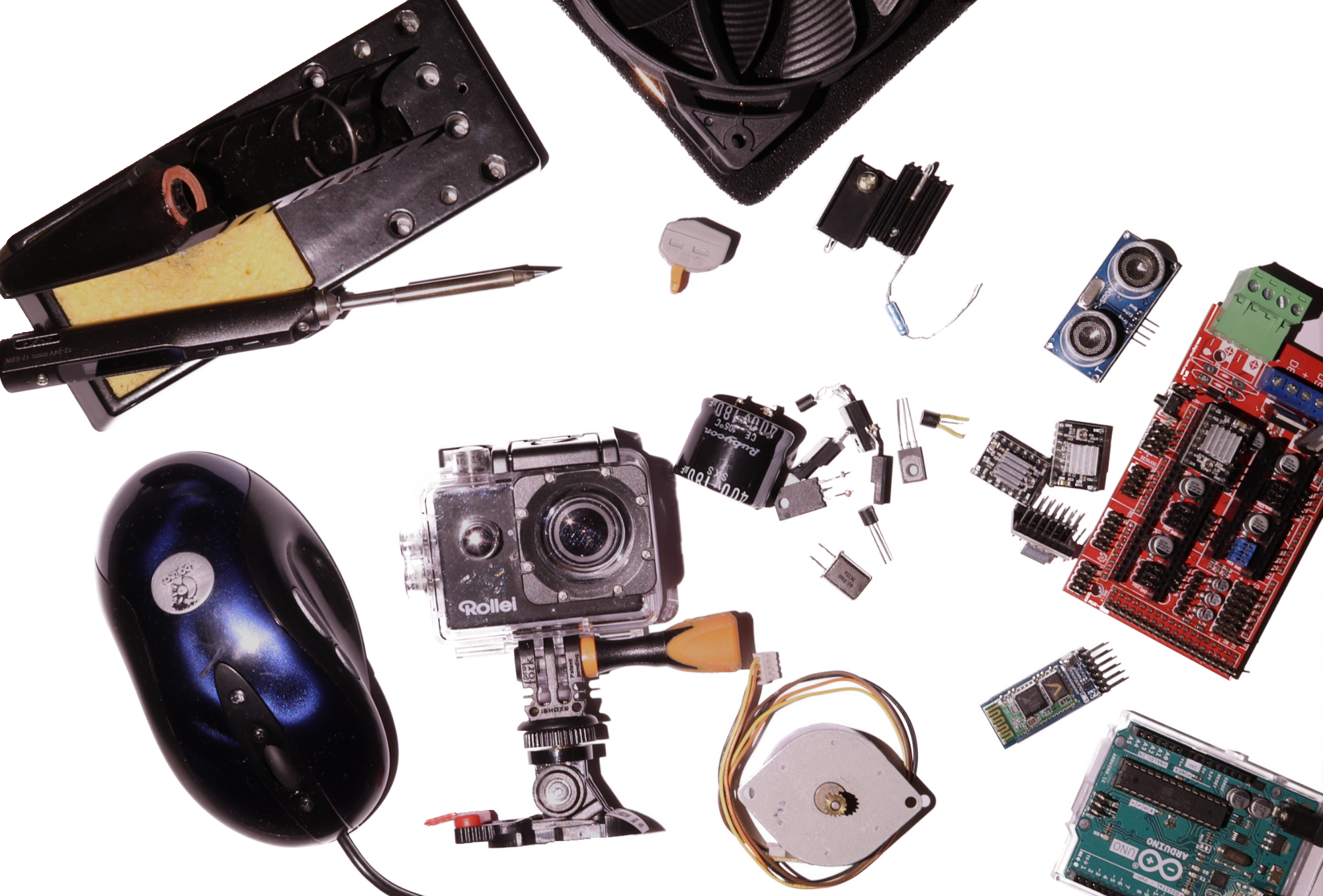

hobbies: electronics and programming

Due to my interest in how things work, combined with the knowledge from the mechatronics and product design, I disassemble electronic devices every now and then to maybe repair them or to reuse their inside components. With the arduino platform I also realize prototypes and small electronics. I have basic knowledge of C, Java and HTML, CSS. This website, for example, is written proudly by myself (with the help of lots of great Youtube-tutorials).